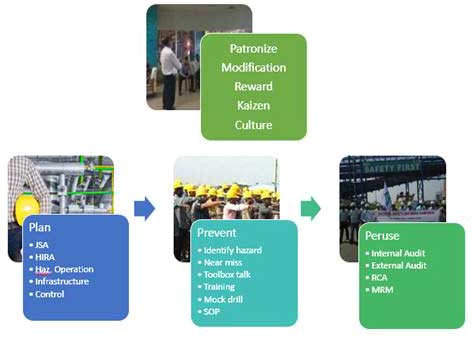

Haldia Energy Limited, from the very beginning of construction period has been following best safety practices not only to avoid injuries, but also to create a safe and healthy work environment.The plant achieved IMS (Integrated Management System for ISO 9001:2008, ISO 14001: 2004, and BS OHSAS 18001: 2007) certification within the first year of its operation and has already migrated to the latest respective ISO versions (2015 version for Quality and Environment and ISO 45001:2018 for Occupational Health and Safety ). Safety Management at Haldia site is structured in the Plan- Do- Check- Act cycle as per IMS standards. HEL has always emphasized to incorporate Safety as a core culture among the employees. “Safety for self and safety for others” has been promoted as a responsibility of all. Safety officers are aiding the safety culture as enablers and provide guidance to adopt best safe practices and benchmark safety processes.

Participation in Safety OathTarget Zero Accident and motto of Zero Harm’

Participation in Safety OathTarget Zero Accident and motto of Zero Harm’

Safety policy is derived from top management guidance and company core values. Top management actively demonstrate safety behaviours and intended interdependency among all inmates irrespective of department and function.

In order to achieve the goal of Zero Accident and Zero harm, we have a rigorous planning process in place to identify and address all the jobs performed at site. Department wise exhaustive list of Hazard Identification and Risk Assessment (HIRA) registers are made to identify and address the significant risks. Job specific Safety Analysis are also done to assess resources required to perform the jobs safely. Job specific safety training requirements are also identified as applicable for different areas.

Area specific Personal Protective Equipment (PPE) matrix is prepared and exhibited locally to mandate minimum PPE requirement depending on environment of a particular area.

Pre-employment health check-up is done for all employees including contracted workforce to determine appropriate area and job nature for individuals.

Prevention of unsafe condition is one of the the primary responsibilities of all working at site. Hazard prevention and near miss incident reporting are part of essential performance indicators of all. Hazard reporting and voicing concern for safety has been enabled in Hindi, English, and Bengali language platform to attract observations from all. State of the art equipment are installed at site to ensure a safe work environment particularly in the vulnerable areas.Regular job specific safety counselling and tool box talk is ensured before start of shift and any critical job.Thorough daily patrolling is also in vogue to monitor the job areas by our safety supervisors. The safety supervisors capture any unsafe acts committed by any workers which are highlighted for appropriate action with a warning.

.jpg)

Beyond Standard

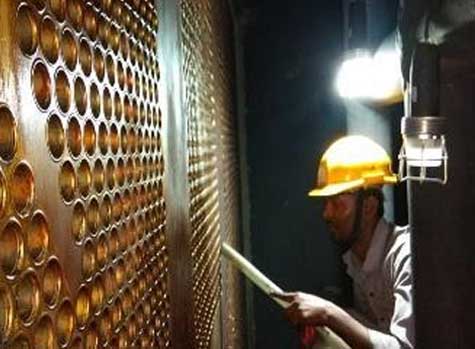

In order to move beyond the standards in all spheres of operation, HEL has initiated world class practices in safety processes. Implementation of 5S is being done to improve effectiveness of housekeeping and to aid safety. Online maintenance of 400 kV transmission lines are being carried out with state of the art safety equipment and with skilled professionals. Electronystagmography, a test to identify people with vertigo is carried out for people involved in work at height. New technology adoptions in the plant include low voltage high lux lights for working in confined spaces, special fire water flow nozzle for single handed operation and body worn camera for remote supervision in closed conduits and other critical areas. Excellence in safety management and safety records has been the integral wheel in HEL’s journey of more than 5 years in commercial operation. We envisage to continue in the path with zero accident and culture of mutual care.

Safety training

Safety training Mock Fire Drill

Mock Fire Drill  Low Voltage high lumen lamp in confined spaces

Low Voltage high lumen lamp in confined spaces

Mock Fire Drill

Mock Fire Drill