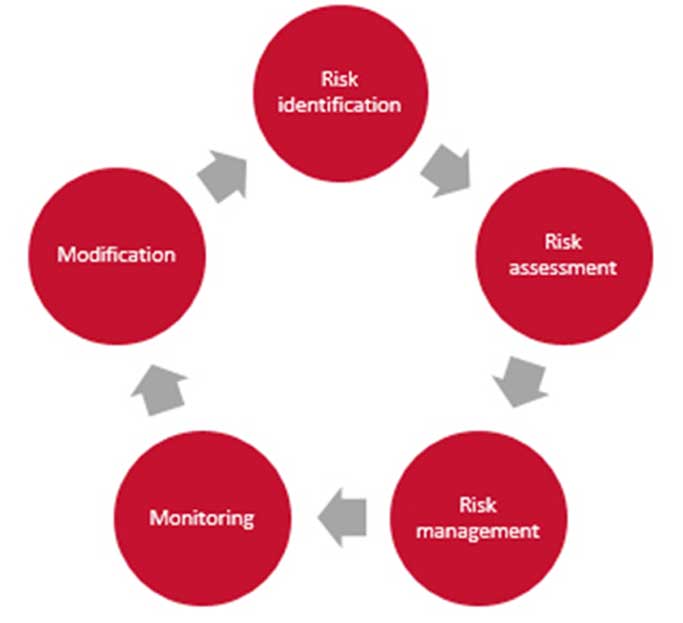

At Haldia Energy Limited, risk Management Standards are designed to help employees not only to identify and manage the major engineering risks involving material and human elements but also what action plan one must follow in situations of crisis to prevent greater damage to the asset.

The Asset Maintenance & Reliability Management system captures and analyses innumerable data through cloud computing and big data analysis, providing a complete picture of plant health. Digital models are built using sensor data so that a predictive maintenance strategy can be developed and implemented.