In an ever-changing world, HEL, through innovation and adoption of best practices, has always been refining its processes to improve efficiency, performance, and reliability. Despite deploying state of the art machines and technologies, the HEL team makes sure that no stone is left unturned to grab any further scope of improvement under all operating conditions. The performance enhancement initiatives have continually helped to optimize fuel consumption and associated emissions.

HEL has been continuously placed among the top-performing private power plants in terms of performance parameters. A strong commitment towards excellence in all verticals of operation is the key driver behind this achievement. The drive for out-of-the-box thinking and innovation has been imbibed as a culture among the entire workforce. Different cross functional teams and a number of forums along with recognition schemes have encouraged people to take a new look into the existing system so that the status quo is challenged to bring in new improvements.

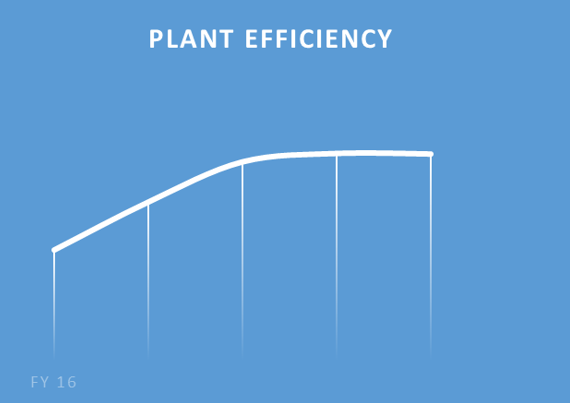

Plant Efficiency

The increase in efficiency leads to less thermal energy consumption which in turn reduces CO2 emission per unit of energy generated. The company has taken a number of innovative measures for improvement of efficiency. While identification and restriction of controllable losses are of primary importance, emphasis is also put to stretch the limits for further improvement.

Extensive use of Thermography for detecting heat losses, modification of oil firing system for the reduction of Fuel Oil consumption, reducing unplanned shutdowns, regular monitoring of performance parameters are part of controllable loss restriction. A number of forums and platforms are created for inviting new ideas for continual improvement in the performance parameters. HEL has been successful in achieving better equipment performance harnessing opportunities leading to efficient and reliable operation of the plant.

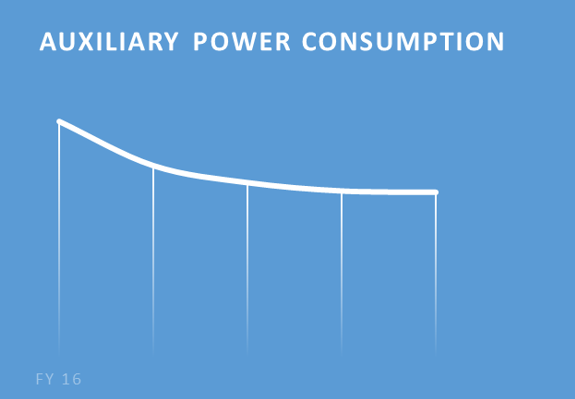

Auxiliary Power Consumption

HEL has taken several measures for energy saving in the area of auxiliary power consumption which has decreased over time. This could be achieved with the incorporation of initiatives through series of experimentations in different fields & optimum capacity utilization of all critical auxiliaries. Some of them are optimizing power setting for ESP and ash conveying system, innovative modifications of hydraulic machines, developing a strategic operating regime to run some critical and high energy-consuming auxiliaries, introducing VVVF controllers, green building initiatives etc.Customised softwares developed inhouse have been introduced to indicate the best operating regime under any operating condition on a real-time basis for optimum use of auxiliary power.

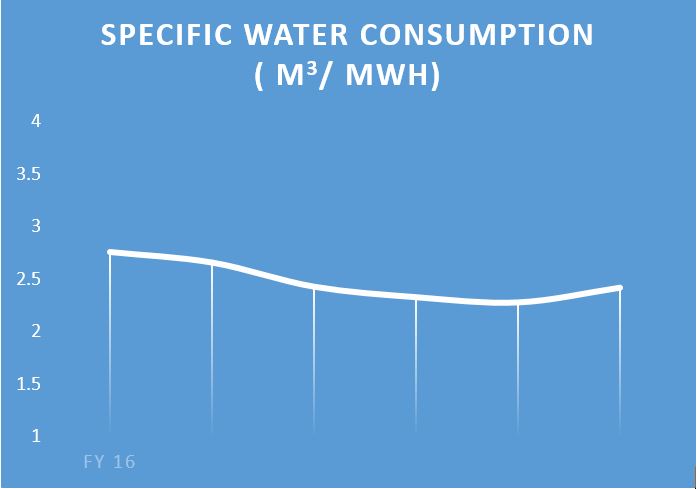

Water Consumption Efficiency

As a step forward, HEL is continually improving on water usage efficiency by reducing, recycling and reusing water to the extent possible. Consumption has not increased in the last few years due to continual efforts in reduction of Specific Water Consumption by resorting to various initiatives. Stringent process parameter control, All Volatile Treatment for boiler water, prevention of water and steam leakages, rainwater harvesting, effluent water recycling, etc. have helped HEL reduce Specific Water Consumption figure over the years and contain it well below the maximum limit of 3.5 Cu Meter/MWh.